Product information

Reviews

Shipping & returns

Product information

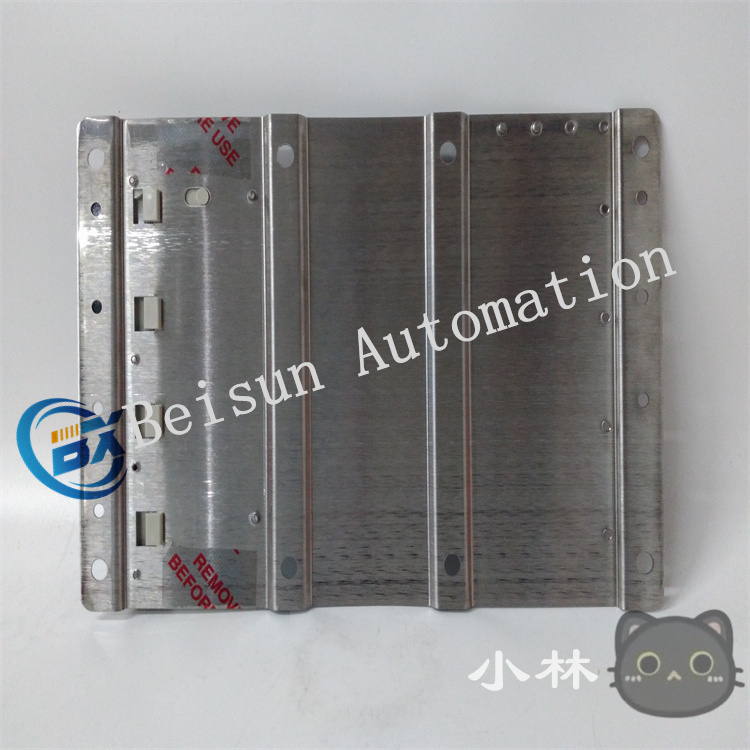

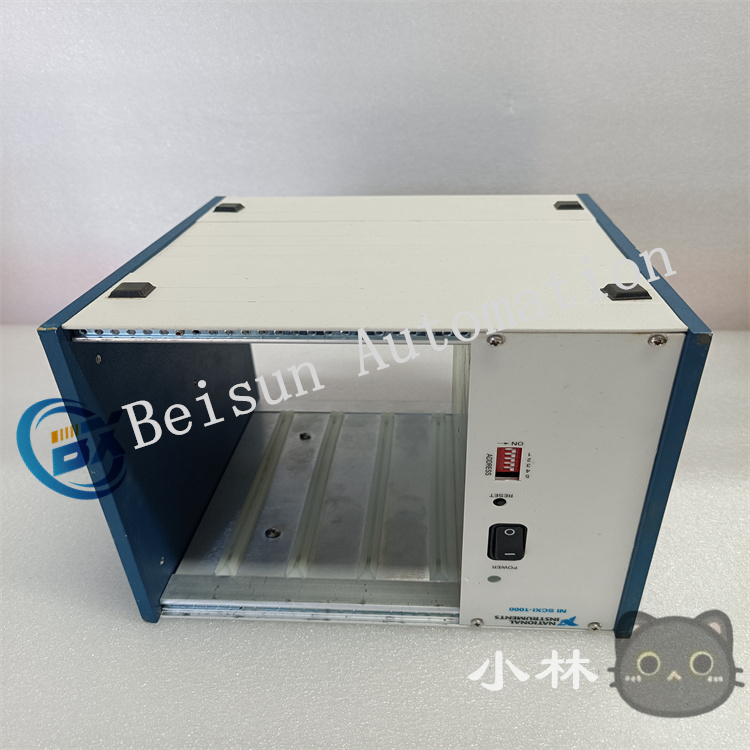

NI SCXI-1121 8-channel strain gauge input module

Characteristics

Channel characteristics: It features 8 independent channels, each of which can be independently connected to a strain gauge sensor. It can simultaneously monitor the strain at multiple measurement points and is suitable for scenarios where strain measurement is required for complex structures or multiple parts.

Input range: Supports multiple strain gauge input ranges, which can adapt to strain gauges of different sensitivities and ranges. Generally, it can cover the measurement range from microstrain to thousands of microstrains, meeting various engineering measurement and experimental requirements.

Excitation methods: Multiple excitation methods are provided, including constant pressure excitation and constant current excitation. The appropriate excitation mode can be selected based on the type of strain gauge and actual application to ensure the accuracy and stability of the measurement.

Signal conditioning: Each channel integrates a signal conditioning circuit, including amplifiers, filters, and bridge completion circuits, etc. The amplifier can amplify weak strain signals. The gain can be set through software programming and generally has a wide gain range, such as 1 to 1000 times selectable. The filter is used to filter out high-frequency noise in the signal. The cut-off frequency can be adjusted according to the actual situation to improve the signal quality. The bridge circuit completion circuit facilitates the connection of different types of strain gauge bridge circuits, simplifying the system design and wiring.

Application field

Structural health monitoring: It is used for health monitoring of Bridges, buildings, large mechanical structures, etc. By measuring the strain changes in key parts, it assesses the stress state and potential damage of the structure, achieving early warning and preventive maintenance.

Material mechanics experiments: In the mechanical property testing experiments of materials, such as tensile tests, compressive tests, and bending tests, they are used to measure the strain of materials during the loading process. Combined with the load data, the stress-strain relationship, elastic modulus, yield strength and other mechanical property parameters of the materials can be analyzed.

Mechanical engineering testing: In the process of mechanical design and manufacturing, it is used to test the strain of mechanical parts under actual working conditions, such as strain measurement of engine crankshafts, gear shafts, pressure vessels, etc., providing a basis for optimized design and strength verification.

Reviews

There are no reviews yet.