Product information

Reviews

Shipping & returns

Product information

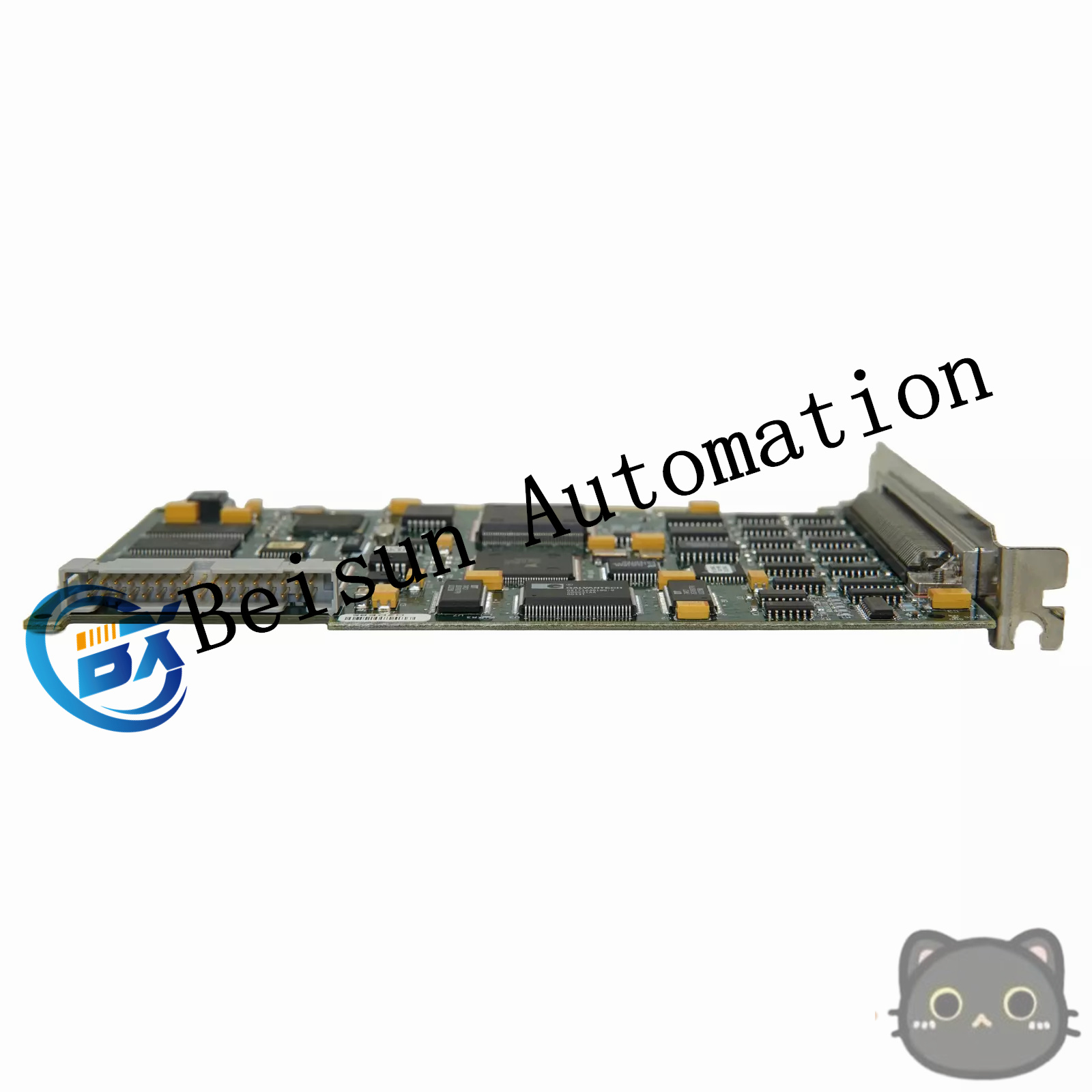

NI PCI-1422 16-bit digital image acquisition card

Functional characteristics

High-resolution image acquisition: Supports 8-bit, 10-bit, 12-bit, 14-bit and 16-bit data acquisition, capable of meeting image acquisition tasks with different precision requirements. At a pixel clock rate of 40MHz, a acquisition rate of up to 80MB/s can be achieved, enabling high-speed, large-image, and high-resolution digital image capture.

Multiple camera interfaces: There are two versions, one compatible with digital cameras using RS422 signals, and the other compatible with digital cameras using LVDS (low-voltage differential signals). They can be connected to various types of digital cameras, adapting to different application scenarios and camera devices.

On-board memory: Equipped with 16MB or 32MB of on-board memory, it provides flexible image buffering for large image capture and continuous real-time data transmission, helping to avoid data loss or transmission bottlenecks.

Flexible triggering method: It provides 4 external TTL triggers, which can be used as high-speed digital input/output lines or trigger signals. Users can configure these trigger signals to precisely control the timing of image acquisition. It also supports the RTSI (Real-time System Interface) bus, enabling synchronization with other NI data acquisition and motion control devices to achieve more complex system integration.

Image preprocessing function: Equipped with a 64KB× 16-bit lookup table (LUT), it can be configured to perform conventional imaging programs such as data inversion, contrast enhancement, or other nonlinear transfer functions, to conduct real-time preprocessing of images during the acquisition process and improve image quality.

Application field

Industrial visual inspection: It is used for product appearance inspection, defect identification, size measurement, etc., helping enterprises achieve automated quality control and production process monitoring.

Scientific research: It is applicable to image acquisition and analysis in scientific experiments such as microscope imaging, high-speed photography, and astronomical observation, providing high-quality image data for researchers.

Machine vision system: As the core component of the machine vision system, it provides visual information for robots, automated production lines, etc., and realizes functions such as target positioning, posture recognition, and path planning.

Reviews

There are no reviews yet.