Product information

Reviews

Shipping & returns

Product information

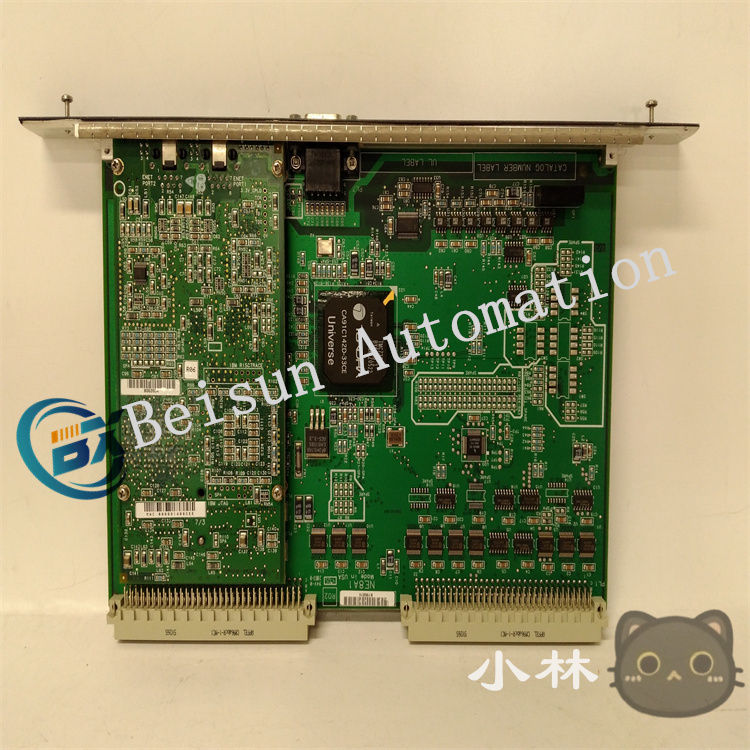

GE IC698ETM001 Ethernet communication module

Basic specification

Operating temperature range: 0°C to 60°C.

Storage temperature range: -40°C to 85°C.

Humidity: The relative humidity ranges from 5% to 95% and does not condense.

Functional characteristics

Communication capability: This module enables the connection of PACSystems RX7i programmable logic controller (PLC) to Ethernet network. It supports a variety of Ethernet communication protocols, such as Ethernet/IP, Modbus TCP, etc., and can communicate with other devices that support the same protocol (such as industrial computers, human machine interfaces (HMI), frequency inverters, etc.).

Data transmission: It can transmit data at high speed, and the Ethernet rate supported is 10/100 Mbps adaptive, ensuring that the data is transmitted quickly and stably between the PLC and the network equipment, and meeting the real-time requirements of the industrial automation system.

I/O mapping: PLC I/O data can be mapped to Ethernet communication, so that remote devices can read and write PLC I/O data, so as to achieve remote monitoring and control functions.

Diagnostic function: With diagnostic function, the working status and fault information of the module can be displayed through the LED indicator, which is convenient for users to troubleshoot and maintain.

Application scenario

Industrial automation production line: In the automated production line, IC698ETM001 can enable PLC and all kinds of automation equipment (such as robots, sensors, actuators, etc.) to communicate through Ethernet, to achieve centralized control and monitoring of the production line, improve production efficiency and quality.

Process control: In chemical, electric power, water treatment and other process control industries, this module can make PLC and host computer system (such as SCADA system) communication, to achieve real-time monitoring and control of the production process, to ensure the safe and stable operation of the production process.

Remote monitoring and maintenance: With the help of Ethernet network, remote PLC can be monitored and maintained. The operator can access the PLC through the network in the office or other locations to read the equipment status, modify parameters, download programs, etc., reducing the workload and cost of on-site maintenance.

Reviews

There are no reviews yet.