Product information

Reviews

Shipping & returns

Product information

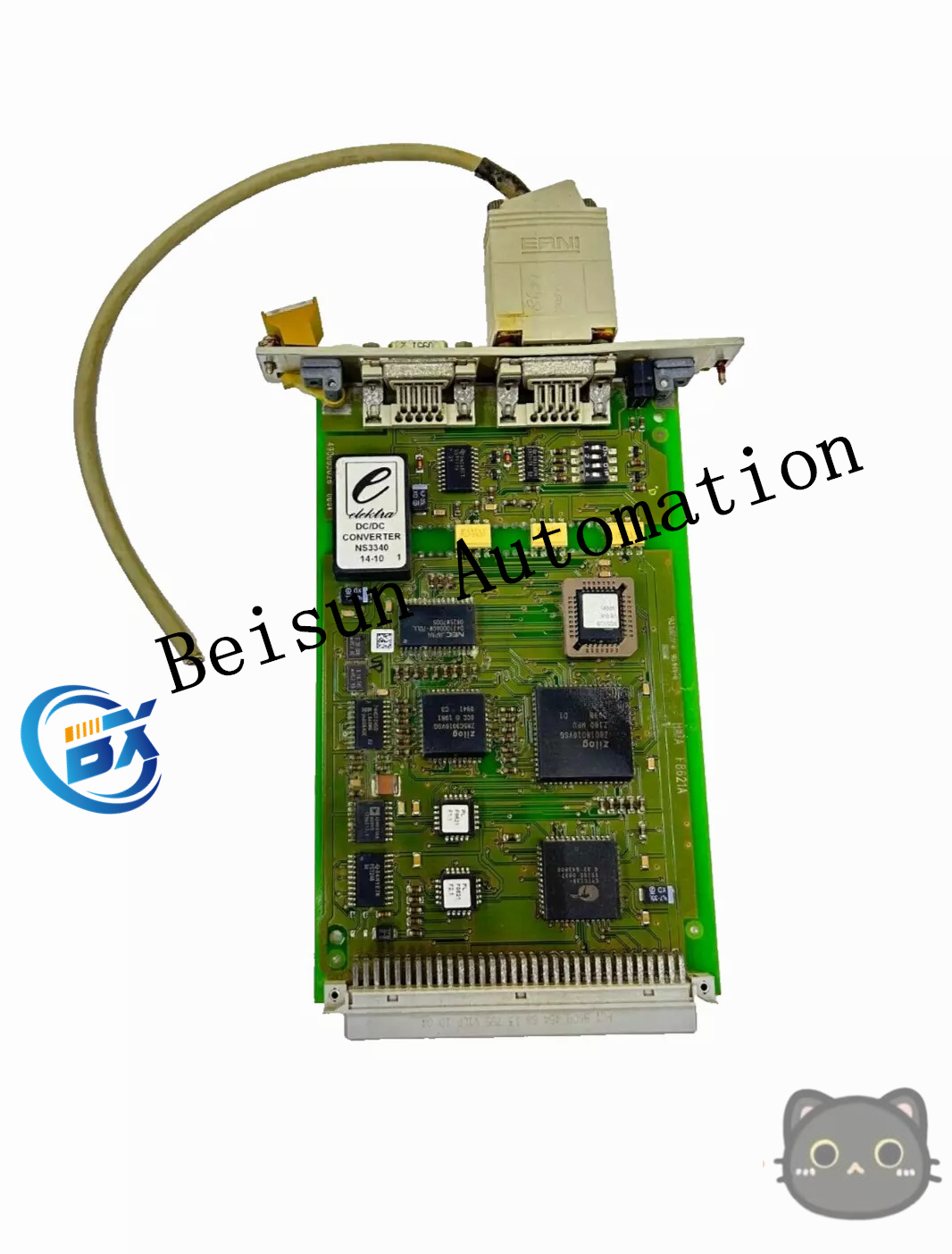

HIMA F-8621A communication processing module

Hardware specification

Processor: Using high-performance processor, can quickly process a variety of communication tasks and data, to ensure the real-time and stability of the system. Specific processor models are usually customized by HIMA for industrial applications, with optimized instruction sets and processing capabilities to efficiently handle complex operations such as communication protocol stacks and data encryption.

Memory: Equipped with a moderate amount of memory, including Cache and random access memory (RAM). The Cache speeds up the access to common data and increases the processing speed. RAM is used to store running programs and data, generally has a large capacity, can support multiple concurrent communication connections and a large number of data buffering processing.

Communication interface: provides a rich communication interface, common Ethernet interface (RJ45), support standard Ethernet protocol, can be used to connect other equipment in the local area network, such as PLC, HMI, server, etc., to achieve high-speed data transmission and network communication; At the same time, it may also be equipped with serial interfaces, such as RS-232 or RS-485 interfaces, which are used to connect with some traditional industrial equipment or instruments with serial communication functions to achieve point-to-point or multipoint communication.

Software function

Communication protocol support: Support a variety of industrial communication protocols, such as Profibus, Profinet, Modbus TCP, OPC UA, etc. This enables the F-8621A to communicate and integrate with equipment from different manufacturers, facilitating the construction of complex industrial automation systems. For example, the Profibus protocol enables communication with Siemens PLC, and the Modbus TCP protocol enables data interaction with Schneider equipment.

Protocol conversion and data processing: With the function of protocol conversion, data of different protocols can be converted and adapted, so that devices with different communication protocols can achieve seamless communication. At the same time, it can also process the communication data, such as data filtering, data format conversion, data packaging and unpacking, etc., to meet the requirements of different devices on data format and content.

Configuration and programming: With dedicated configuration software, engineers can configure and program the F-8621A. You can set communication interface parameters, such as IP address, subnet mask, and baud rate. You can also define parameters for communication connections, such as connection type, timeout, number of retries, and so on. In addition, some custom communication logic and data processing algorithms can be programmed to meet the needs of specific industrial applications.

Application field

Industrial automation production line: used to connect various automation equipment on the production line, such as robots, conveyor belts, PLC controllers, etc., to achieve collaborative work and data sharing between devices, improve production efficiency and product quality.

Process control system: In chemical, petroleum, electric power and other process industries, used to connect distributed control system (DCS), field instruments and actuators, to achieve real-time monitoring and control of the production process, to ensure the safe and stable operation of the production process.

Smart factory: As a communication hub in the smart factory, it connects various intelligent devices, information systems and cloud platforms in the factory to achieve information and intelligent management of the factory, such as production scheduling, equipment operation and maintenance management, energy management, etc.

Reviews

There are no reviews yet.