Product information

Reviews

Shipping & returns

Product information

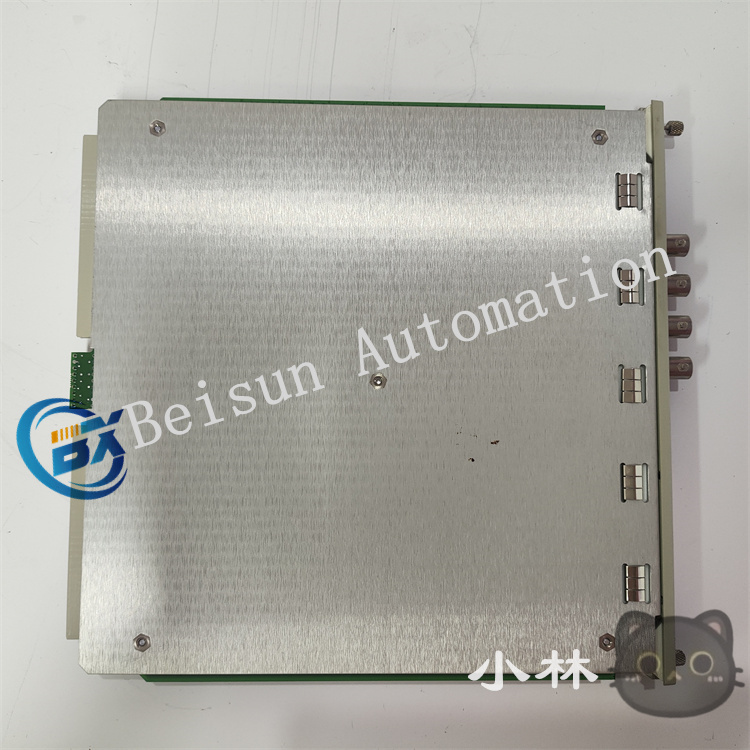

HIMA F-7126 Safety digital input module

Functional characteristics

High safety: It meets relevant industrial safety standards, such as SIL (Safety Integrity Level) certification, usually up to SIL level 3, and can be used in safety-critical application scenarios to ensure the reliable operation of the system in hazardous environments and effectively prevent safety accidents caused by module failure or incorrect input.

Reliability: Using high-quality electronic components and advanced manufacturing process, after strict quality inspection and environmental testing, can work stably in harsh industrial environment, with a long mean time to failure (MTBF), can adapt to high temperature, high humidity, strong electromagnetic interference and other industrial field environment, reduce the system downtime caused by module failure. Improve the reliability and availability of the entire industrial automation system.

Flexibility: Support for multiple communication protocols for seamless integration with different types of control systems, such as HIMA’s own safety control system, as well as other mainstream PLC, DCS systems, etc. Its modular design makes it easy to add or replace modules when the system is expanded or retrofitted to meet the needs of industrial automation projects of different sizes and complexity.

Application field

Petrochemical industry: In the process of petroleum refining and chemical production, it is used to collect the switching signal of various process parameters, such as the start and stop state of the pump, the open and close state of the valve, the pressure switch signal, etc., to provide accurate field equipment status information for the safety control system to ensure the safe and stable operation of the production process.

Power industry: In power plants, substations and other places, it can be used to monitor the status of electrical equipment, such as the on-off state of the circuit breaker, the position signal of the isolation switch, the action signal of the protection device, etc., to provide basic data for the automatic control and protection of the power system, and ensure the reliable power supply of the power system.

Metallurgical industry: In the process of steel production, it is used to collect various switching signals of blast furnace, converter, continuous casting machine and other equipment, such as the operating status of equipment, fault alarm signals, and position signals of material conveying system, etc., to realize the automatic control and monitoring of the metallurgical production process, and improve production efficiency and product quality.

.jpg)

.jpg)

-2.jpg)

Reviews

There are no reviews yet.