Product information

Reviews

Shipping & returns

Product information

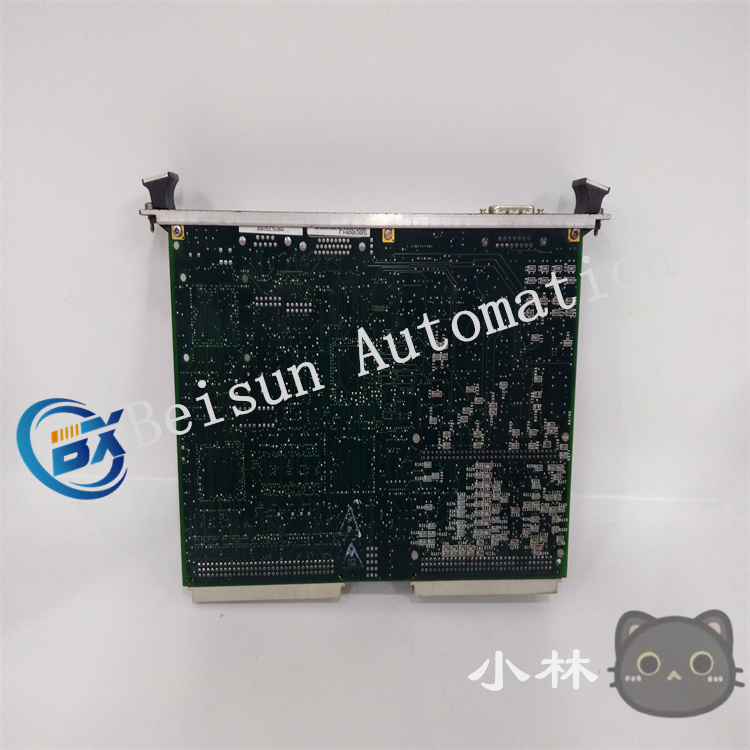

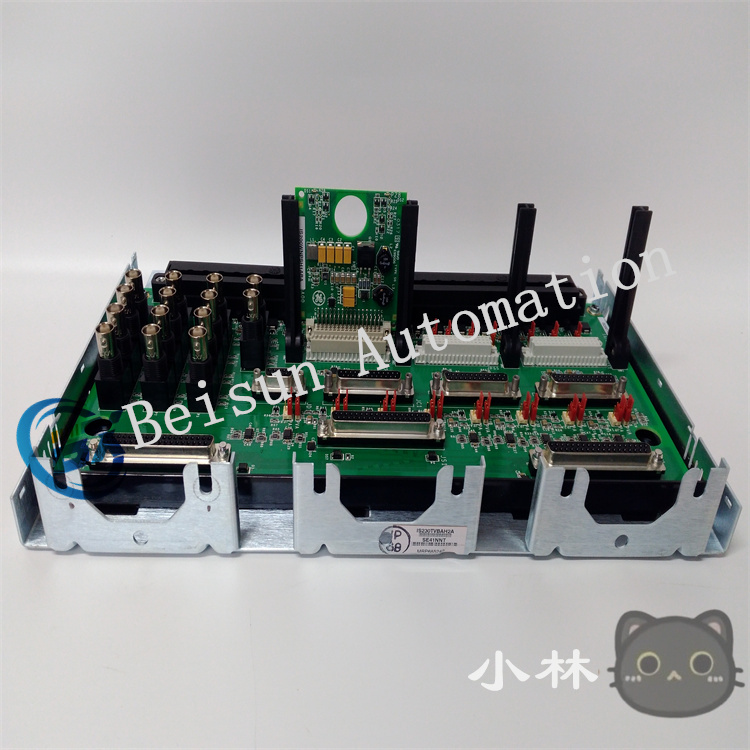

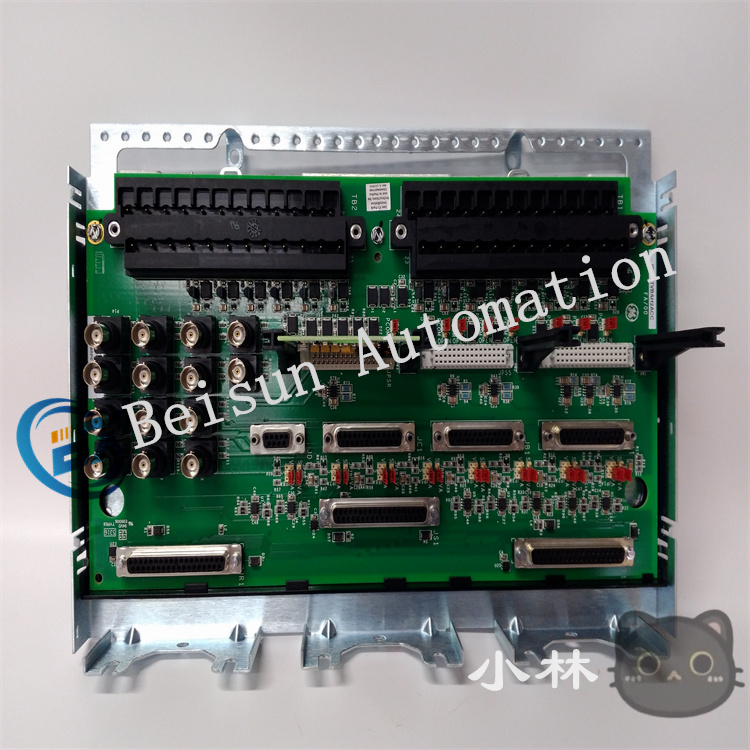

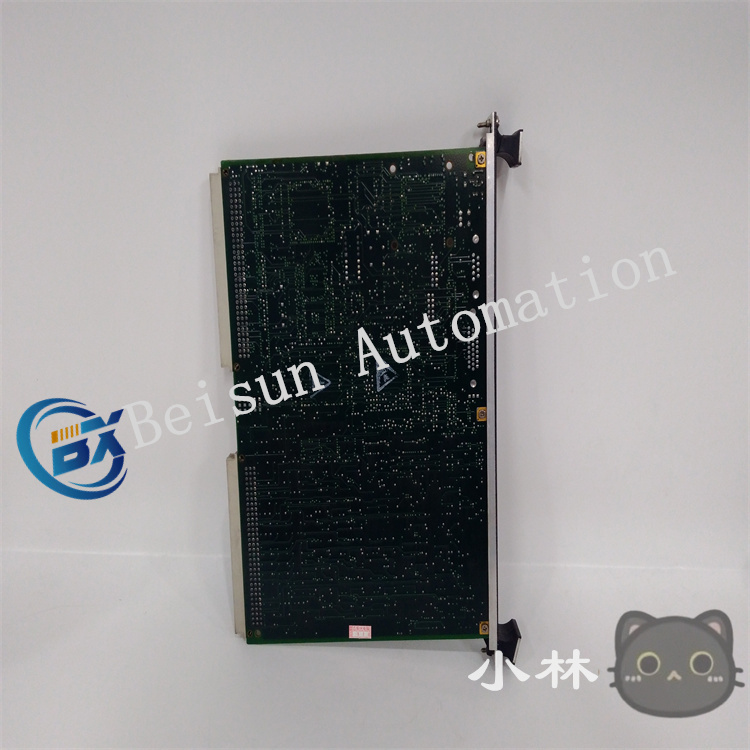

GE 369-H1-R-0-0-0 Multilin motor management relay

Technical parameter

Power supply: 50-300 VDC / 40-265 VAC.

RTD inputs: There are 12 optional RTD inputs that can be connected to platinum RTD (100 ohms), nickel RTD (100 ohms, 120 ohms) or copper RTD (10 ohms) for monitoring bearing, stator and ambient temperature.

Communication: Support Modbus RTU protocol communication, can be connected to the computer through non-isolated RS232 port or RS485 port, with Enervista 369 software for motor status monitoring, relay function maintenance and data integration.

Other: Operating temperature range from -40 °C to + 60°C, storage temperature range from -40 °C to + 80°C, altitude not exceeding 2000 m, relative humidity up to 95% (non-condensing).

Functional characteristics

Protection function: Automatic undervoltage restart, reverse power, starter failure, kVA requirement, kvar requirement, kW requirement, current requirement, reverse spin detection, self-test/service, trip counter, lost RRTD communication, open/open RTD, short/low temperature RTD, environment RTD, acceleration timer, Mechanical block, Restart block (reverse timer), Start Disable (available heat capacity), heat capacity, reactive power, main switch, differential switch, lock, over/under frequency, alarm, starts per hour/Start interval, overvoltage protection, power factor, overload protection, ground fault and ground fault backup, Short circuit backup, Stator RTD, voltage reversal, current imbalance protection, bearing RTD, undercurrent/underpower protection, undervoltage protection and speed switch and other protection functions.

Learning and adaptability: The ability to “learn” individual motor parameters and adjust them for specific applications, and the user can manually adjust motor surge current, cooling rate and/or acceleration time to optimize protection performance.

Monitoring and display: Various operating parameters of the motor can be monitored, which can be viewed on the relay’s 40-character LCD screen or more easily on a computer running the Enervista 369 software.

Application: It is widely used in the industrial field requiring accurate control and reliable protection of large and medium-sized three-phase motors, such as electric power, metallurgy, chemical industry, mining, paper making, water treatment and other industries, as well as a variety of equipment and systems using large and medium-sized motors, such as pumps, fans, compressors, mixers and so on.

Reviews

There are no reviews yet.