- Home

- Product

- Bently Nevada

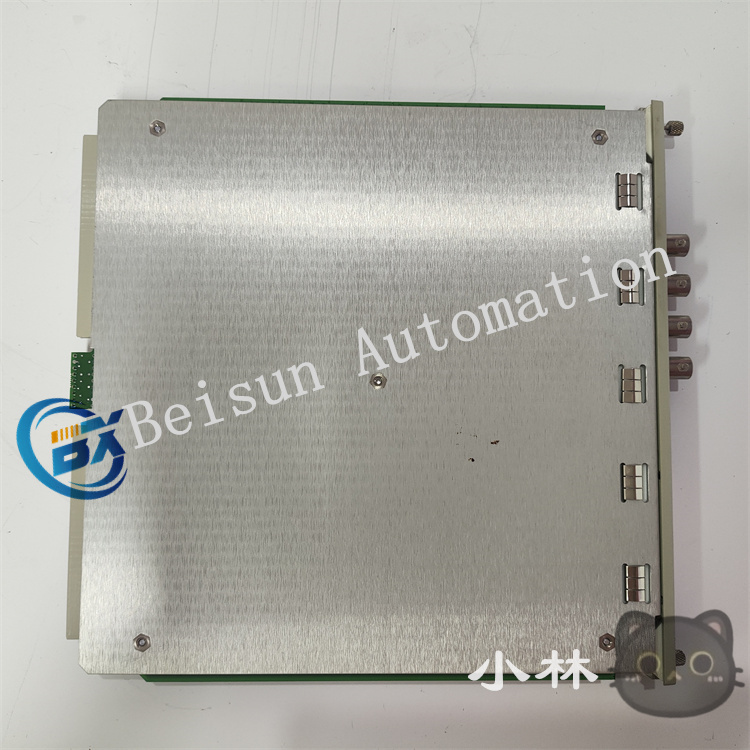

- BENTLY 3500/45-01-00 Expansion differential measurement module

Product information

Reviews

Shipping & returns

Product information

BENTLY 3500/45-01-00 Expansion differential measurement module

Functional characteristics

Multi-type signal input: It is a 4-channel monitor that can receive input signals from the approach eddy current sensor, rotary position sensor (RPT), DC linear variable differential converter (DCLVDT), AC linear variable differential converter (ACLVDT), and rotary potentiometer.

Various measurement functions: axial position, differential expansion, inclined surface differential expansion, compensation differential expansion, shell expansion and valve position can be measured, but only channels 3 and 4 can achieve shell expansion monitoring.

Signal processing and alarm: The input signal is processed and the processed signal is compared with the user programmable alarm Settings. According to the configuration, each channel can process the input signal into a variety of parameters called “proportional values”, each effective proportional value can be configured as an alarm setting point, and any two effective proportional values can be configured as a danger setting point to provide mechanical protection.

Fault diagnosis and output: A TX/RX LED on the front panel indicates the communication status with other modules in the 3500 frame, and a bypass LED indicates the bypass off state for easy fault diagnosis. In addition, each channel should have a coaxial connector on the front panel to buffer the output of the sensor, and the output signal is different when using different types of sensors.

Technical parameter

Operating environment: Operating temperature range is -30 °C to + 65°C, humidity is 95% non-condensing, storage temperature is -40 °C to + 85°C.

Dimension weight: The module size is about 24.13cm×2.44cm×24.18cm, the weight is 0.91kg, and the shipping weight is 2kg.

Application field

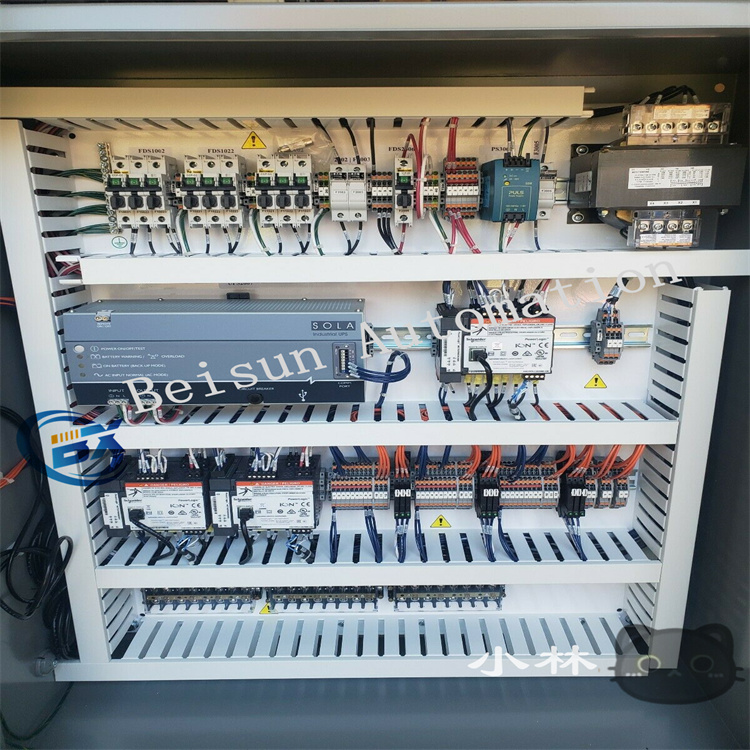

Suitable for power generation, petroleum, metallurgy and other industries, often used for steam turbine, compressor and other large rotating machinery equipment expansion and axial position monitoring, through real-time monitoring of relevant parameters, to help operators find potential problems in time to ensure the safe and stable operation of equipment.

Reviews

There are no reviews yet.