- Home

- Product

- Bently Nevada

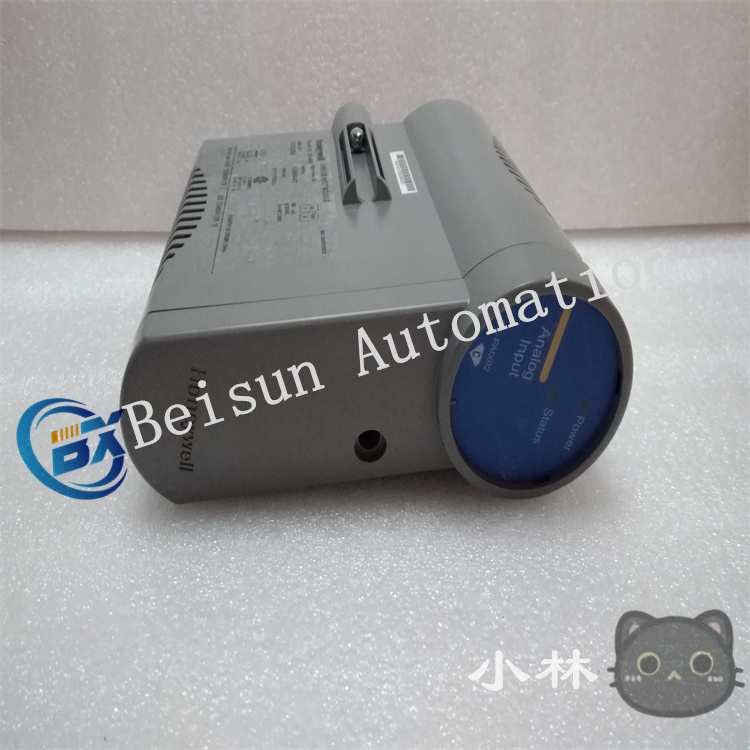

- BENTLY 3500/42-01-00 176449-02 Proximitor earthquake monitor

Product information

Reviews

Shipping & returns

Product information

BENTLY 3500/42-01-00 176449-02 Proximitor earthquake monitor

Functional characteristics

Multi-channel monitoring: It is a four-channel monitor, which can receive input signals from proximity and seismic sensors, and can collect data from multiple monitoring points at the same time to realize comprehensive monitoring of vibration, displacement and other parameters of different parts of rotating machinery.

Signal processing and measurement: The input signal is conditioned to provide vibration and position measurements, and the conditioned signal is compared to user-programmable alarm values. Each channel can be programmed with 3500 rack configuration software to monitor and report radial vibration, thrust position, acceleration, differential expansion, absolute shaft eccentricity, circular acceptance area, speed, and more.

Alarm function: Each channel can generate various parameters (static values) according to the configuration, and configure the alarm set point for each active static value, configure the danger set point for any two active static values, and drive the alarm by continuously comparing the monitoring parameters with the configured alarm set points to protect the machine equipment.

Technical parameter

Input channels: Two channels that can accept input from proximity probes or seismic sensors.

Output: 4-20mA signal, proportional to the measured signal, for external analysis.

Frequency response: Suitable for a wide range of vibration and proximity measurements.

Alarm level: Alarm and danger levels can be configured.

Power Supply: Efficient operation within 3500 rack power specifications.

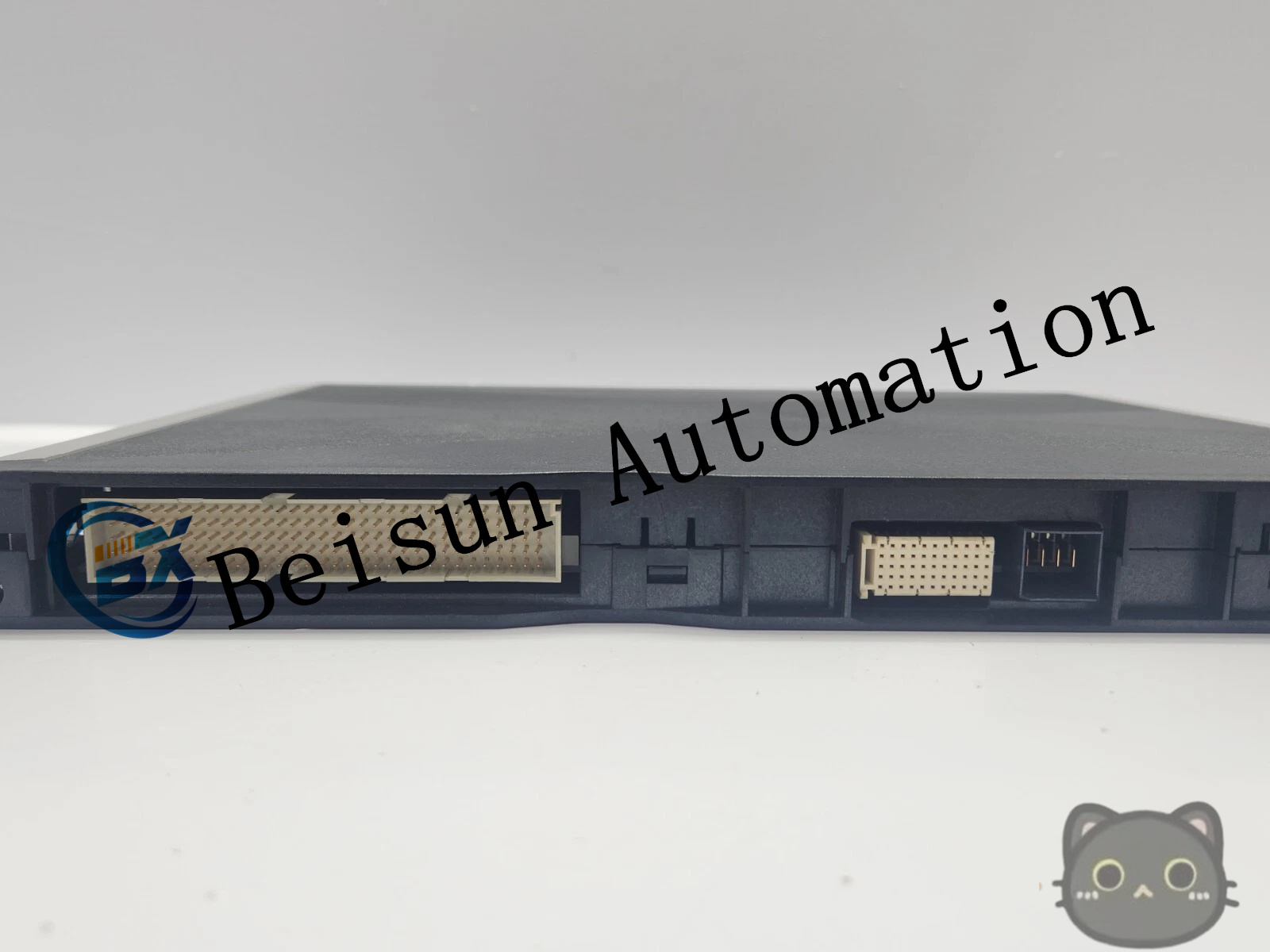

Installation: Easily installed in the 3500 series rack.

Connectivity: Directly integrated with System 1® for detailed diagnostics and data analysis.

Temperature range: Designed for standard industrial temperature ranges to ensure continuous operation.

Application scenario

In the industrial field, it is mainly used for the status monitoring of all kinds of rotating machinery, such as compressors, pumps, steam turbines, generators and other equipment. Through real-time monitoring and analysis of the vibration, displacement and other parameters of these equipment, the hidden trouble of equipment can be discovered in advance, providing scientific basis for the maintenance of equipment, thus effectively reducing the failure rate of equipment and extending the service life of equipment. Increase productivity and reduce downtime and maintenance costs.

Reviews

There are no reviews yet.