- Home

- Product

- Bently Nevada

- BENTLY 3500/42-01-00 138708-01 3500 series monitor

Product information

Reviews

Shipping & returns

Product information

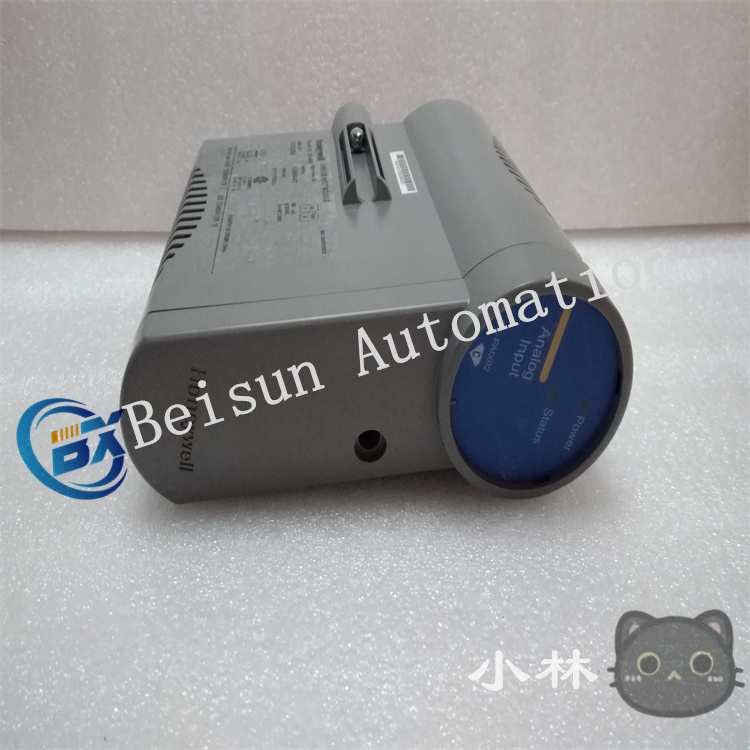

BENTLY 3500/42-01-00 138708-01 3500 series monitor

Technical parameter

Input characteristics: With two input channels, it can accept high-frequency signals from proximity probes (for measuring parameters such as displacement) and vibration signals from seismic sensors. The input signal range is usually ±5V or ±10V to adapt to the output characteristics of different sensors.

Measurement range: For radial vibration measurement, the range is generally 0-250mil (mil); The measuring range of axial displacement is about ±10mm. The speed measurement range can cover 0-100 in/s (inch /s), and the specific measurement range can be adjusted according to the actual configuration and application requirements.

Output signal: Provides 4-20mA analog output, proportional to the measured physical quantity, and can be easily connected to an external display instrument, recorder or other control system. At the same time, it also has a digital output interface, which is used to output discrete signals such as alarm status and equipment status.

Power requirements: The working power supply is usually 24VDC, with a wide range of power supply voltage adaptation, generally about ±10%, to ensure stable operation in different industrial power environments.

Operating temperature range: can work normally in the temperature range of -40 °C to + 85°C, adapt to a variety of harsh industrial site environment.

Application scenario

In industrial production, it is mainly used in the condition monitoring and protection of all kinds of large rotating machinery and equipment. For example, compressors and pumps in the petrochemical industry; Steam turbines and generators in the power industry; Metallurgical industry fan, rolling mill and other equipment is widely used. By monitoring the key operating parameters of these devices in real time, the abnormal conditions of the equipment are found in time, which provides powerful data support for the preventive maintenance of the equipment, thereby improving the reliability and operation efficiency of the equipment, reducing the maintenance cost and downtime, and ensuring the safe and stable operation of the production process.

Reviews

There are no reviews yet.