- Home

- Product

- Bently Nevada

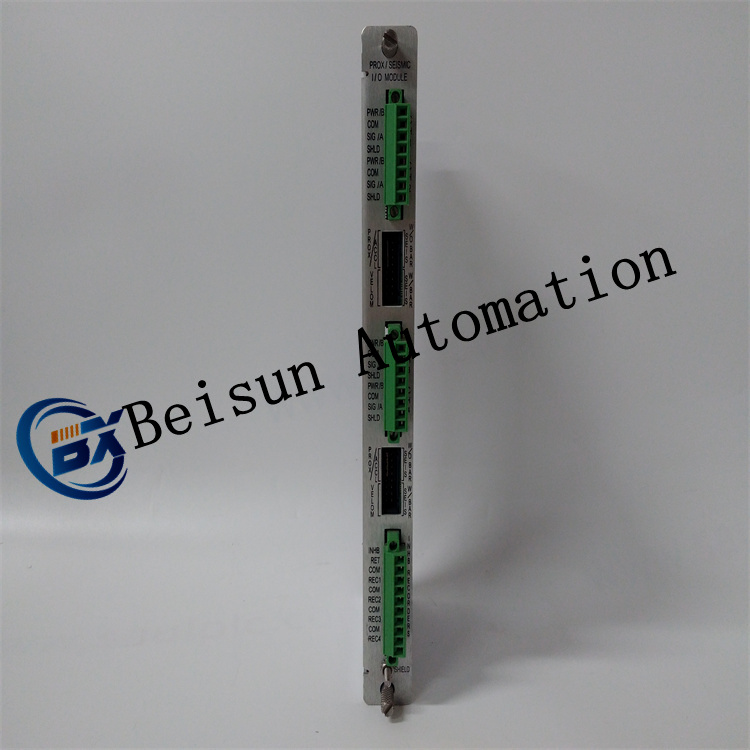

- BENTLY 3500/42-01-00 128229-01 Monitoring module

Product information

Reviews

Shipping & returns

Product information

BENTLY 3500/42-01-00 128229-01 Monitoring module

summarize

3500/42 is a monitor with multiple functions for condition monitoring of rotating machinery, and 128229-01 is a specific version or batch number of this monitor. It is usually installed in the rack of the 3500 series and works in conjunction with other modules to achieve comprehensive monitoring and protection of rotating equipment.

Functional characteristics

Multi-parameter monitoring: It can receive signals from different types of sensors, including but not limited to vibration sensors, displacement sensors, etc., and can monitor various operating parameters of rotating machinery, such as radial vibration, axial displacement, speed, acceleration, etc. Through the real-time monitoring and analysis of these parameters, the operating state of the equipment can be accurately evaluated.

Signal processing and analysis: The built-in advanced signal processing algorithm can filter, amplify, digitize and other processing of the input sensor signal, and calculate a variety of related parameters and characteristic values. For example, it can extract vibration amplitude, frequency components and other information from vibration signals to help operators determine whether there is abnormal vibration and its causes.

Alarm and protection function: Users can set different alarm thresholds for each monitoring parameter through software according to the operating requirements and safety standards of the equipment, including warning threshold and danger threshold. When the monitored parameter exceeds the corresponding threshold, the module will immediately send an alarm signal, and at the same time, through the connection with the external device, the corresponding protection action can be triggered, such as shutdown, load reduction, etc., to avoid equipment damage and accidents.

Data communication and integration: Support a variety of communication protocols, such as RS485, Profibus-DP, Modbus, etc., to facilitate data communication and integration with other control systems or host computers. In this way, the monitoring data can be transmitted to the central control room or remote monitoring center, and the centralized monitoring and management of multiple devices can be realized, so that the operator can timely grasp the operating status of the equipment and make decisions.

Application field

Widely used in petrochemical, electric power, metallurgy, paper, pharmaceutical and other industries of all kinds of rotating machinery equipment, such as large motor, compressor, fan, pump, steam turbine, gear box and so on. Through real-time monitoring and analysis of the operating status of these key equipment, potential trouble can be found in time, and maintenance measures can be taken in advance, thus effectively reducing the failure rate of equipment, reducing downtime, improving production efficiency, and ensuring the safety and stability of the production process.

.jpg)

Reviews

There are no reviews yet.