- Home

- Product

- Bently Nevada

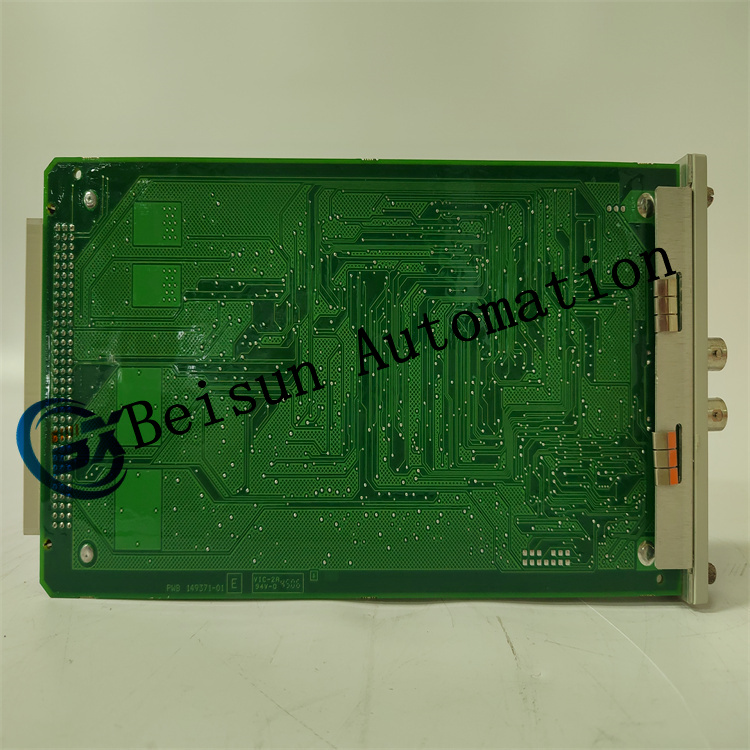

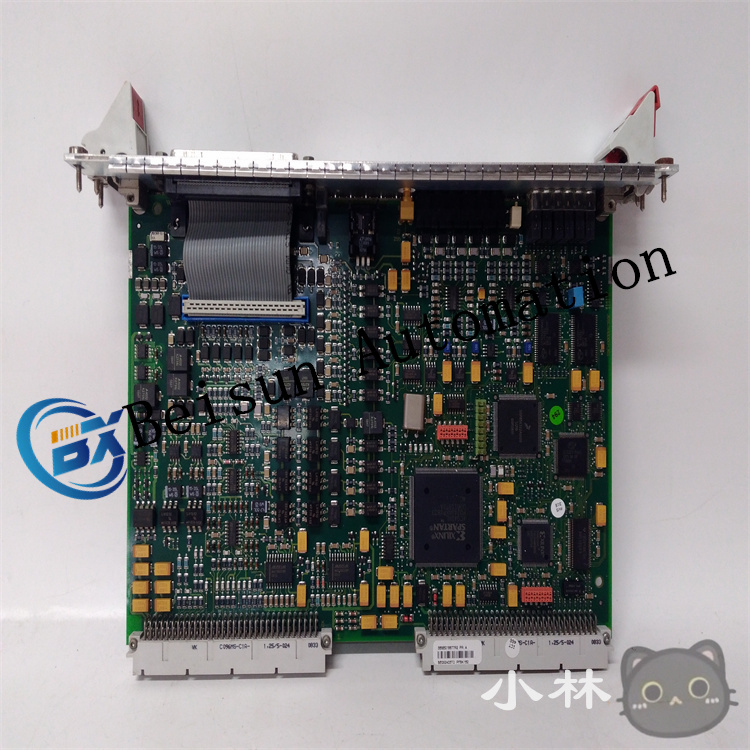

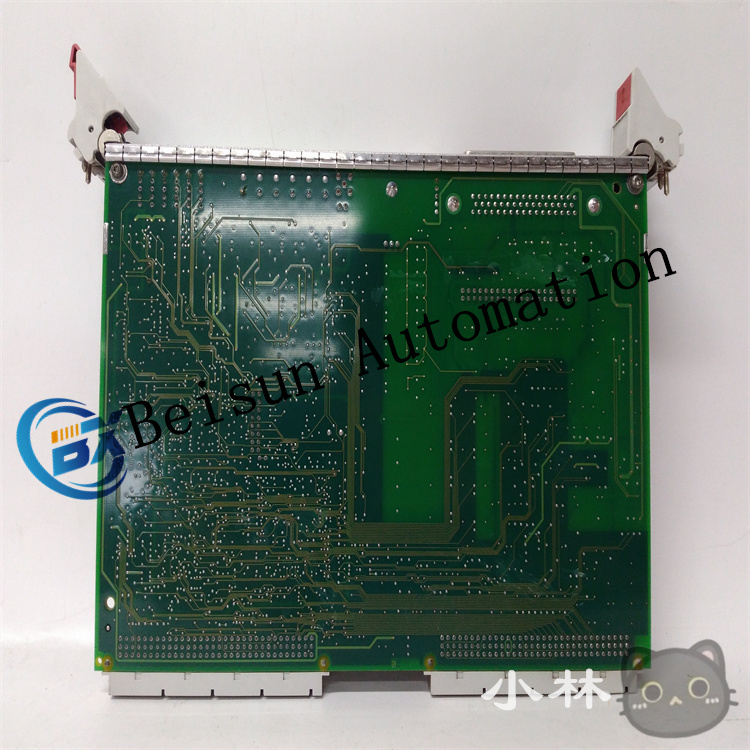

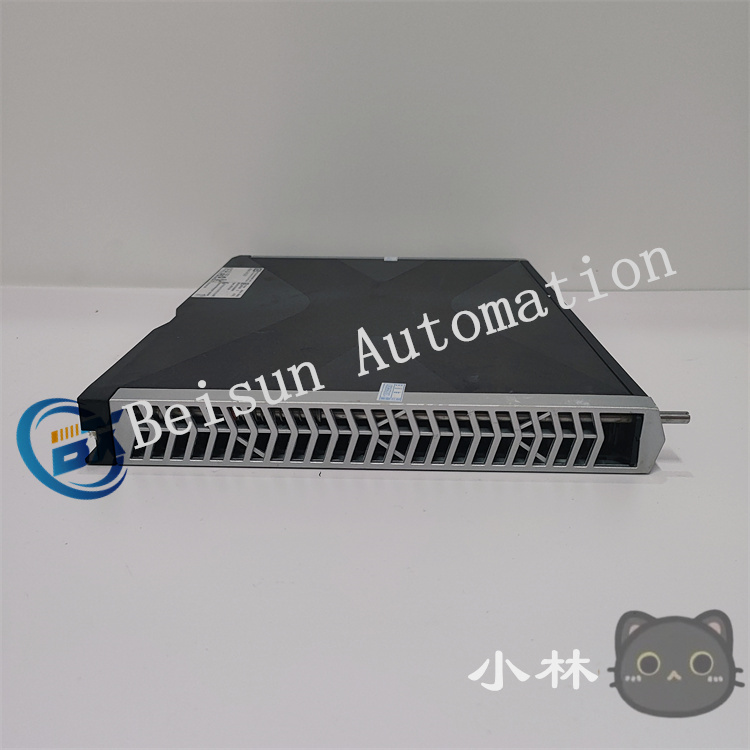

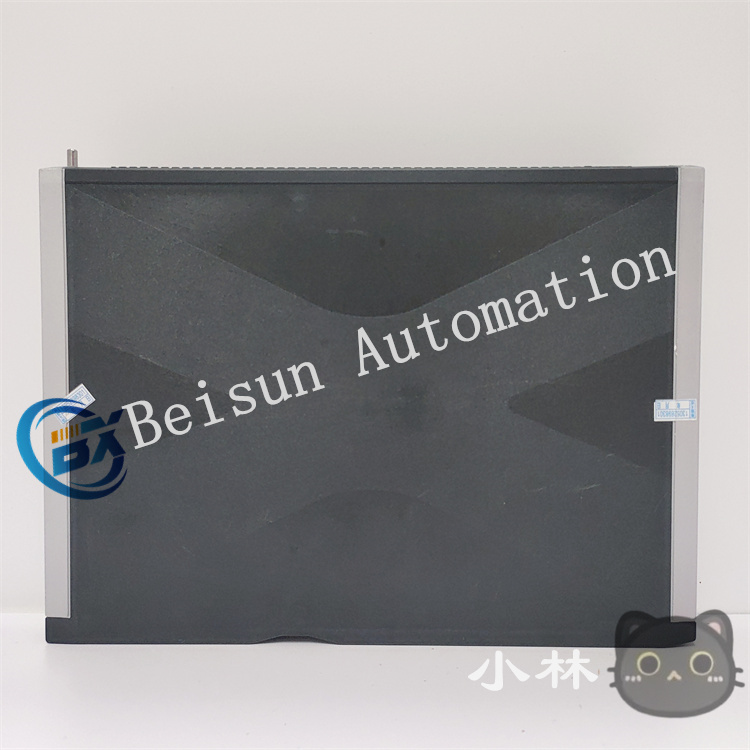

- BENTLY 3500/25 149369-01 Enhanced bond phase module

Product information

Reviews

Shipping & returns

Product information

BENTLY 3500/25 149369-01 Enhanced bond phase module

Features: It is a half-height, dual-channel module used to provide key phase signals to monitor modules in the 3500 frame. It receives an input signal from a proximity detector or magnetic receiver and converts the signal into a digital key phase signal indicating when the key phase marker on the shaft coincides with the key phase sensor, which measures shaft speed and phase. The module features field-upgradeable firmware and asset management data reporting capabilities that generate per-revolution event signals from the input signals of multiple events per revolution, providing the system with more accurate timing measurements, such as shaft speed, 1x vibration amplitude and phase vector parameters.

Technical specification

Size: Height × width × depth is 119.9mm×24.4mm×256.5mm.

Weight: 0.78kg.

Power consumption: Typical value is 3.2 watts.

Input signal range: + 0.8V to -21.0V for non-isolated I/O modules and + 5V to -11V for isolated I/O modules.

Input impedance: Minimum 21.8kΩ.

Input range: 1 to 1200000 CPM (0.017 to 20kHz).

Output range: 1 to 99999cpm (0.017 to 1667Hz).

Output impedance: The maximum buffer output impedance is 504Ω.

Key phase sensor power supply: -24V DC, maximum 40mA per channel.

Operating temperature: -30°C to + 65°C.

System compatibility: The 3500 machine protection system accepts four key phase signals in a normal configuration and eight key phase signals in a paired configuration. In triple module redundancy (TMR) applications, two key phaser modules are typically used to provide the primary and secondary key phase signals. For systems with more than four key phase inputs, a paired configuration is available, providing four primary input channels and four alternate input channels.

Application scenario: Applicable to various industrial scenarios that require accurate monitoring of the running status of rotating equipment, such as the status monitoring and fault diagnosis of large motors, steam turbines, and compressors in the electric power, petroleum, chemical, and metallurgical industries. By providing accurate key phase information, maintenance personnel can learn about the running status of the equipment in a timely manner, detect potential faults in advance, and ensure the safe and stable operation of the equipment.

Reviews

There are no reviews yet.