- Home

- Product

- Bently Nevada

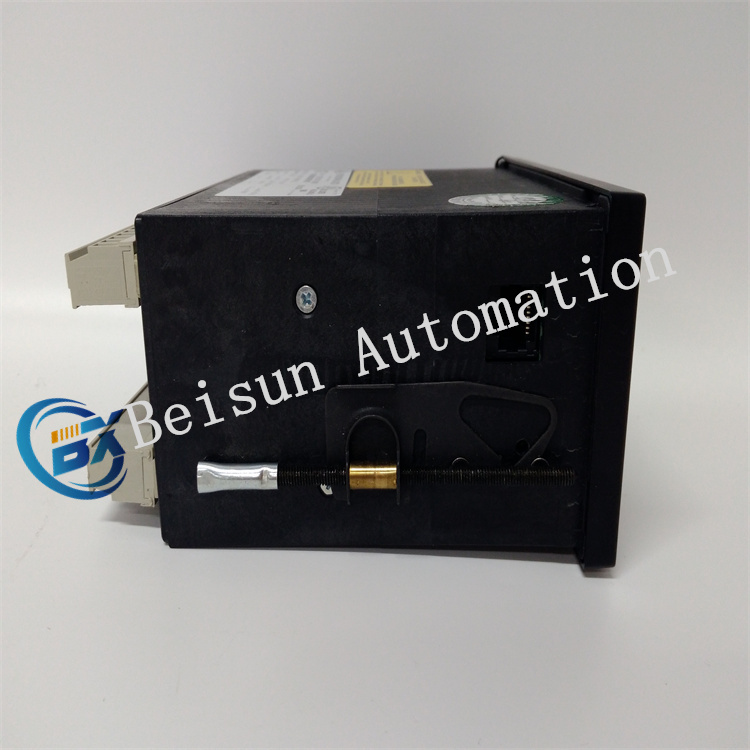

- BENTLY 3300-1-1 sensor preprocessor

Product information

Reviews

Shipping & returns

Product information

BENTLY 3300-1-1 sensor preprocessor

Functional characteristics

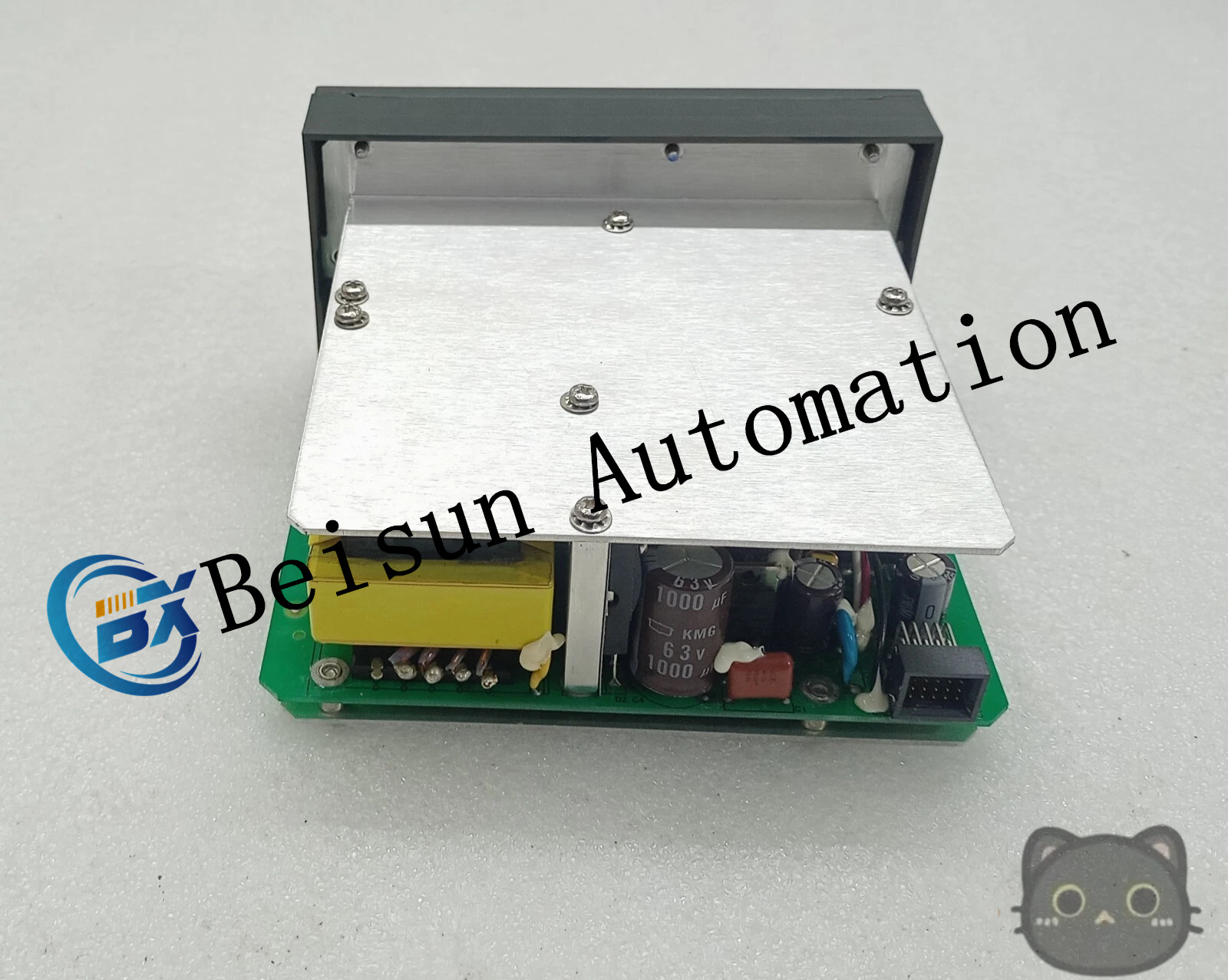

Signal conversion: It is mainly used to convert the non-electrical signal related to rotor displacement detected by the eddy current sensor into an electrical signal that can be processed, providing the basis for subsequent monitoring and analysis.

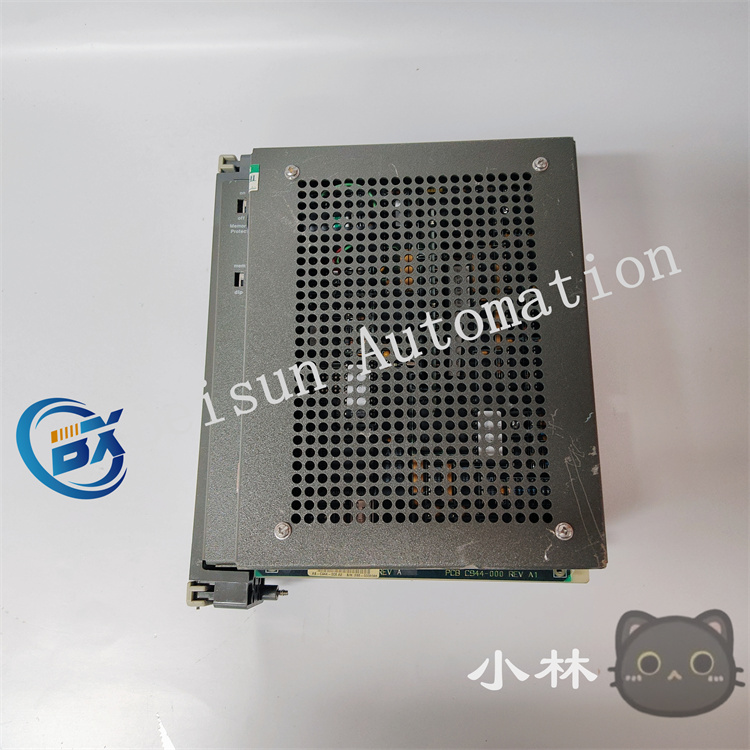

High reliability: Designed for harsh industrial environments, it can work stably under high temperature, high vibration and other conditions to ensure the accuracy and reliability of measurement.

Good linearity: With good linearity, it can accurately convert the displacement measurement value of the sensor into the corresponding electrical signal output, ensuring the authenticity of the measurement results.

Technical parameter

Input characteristics: Suitable for specific types of eddy current sensors, can receive the weak signal from the sensor, and effectively amplify and process.

Output signal: Usually output standard DC voltage signals, such as -20V to +20V or 4mA to 20mA, in order to interface with subsequent monitoring equipment such as monitoring instruments, data acquisition systems, etc.

Operating temperature range: Generally can work in the temperature range of -40℃ to +85℃, to meet the environmental temperature requirements of most industrial sites.

Power requirements: A stable DC power supply, such as +24V DC power supply, is required to ensure normal operation.

Application field

Petrochemical industry: Used to monitor the shaft displacement, shaft vibration and other parameters of various large rotating equipment, such as compressors, pumps, steam turbines, etc., to ensure the safe operation of equipment and prevent production accidents caused by rotor failure.

Power industry: In generators, motors and other equipment, it is used to monitor the operating status of the rotor in real time, find potential trouble spots in time, and improve the reliability and stability of power equipment.

Metallurgical industry: The condition monitoring of rotating machinery such as large fans and rolling mills in metallurgical production helps to optimize equipment maintenance plans, reduce downtime and improve production efficiency.

Reviews

There are no reviews yet.