Product information

Reviews

Shipping & returns

Product information

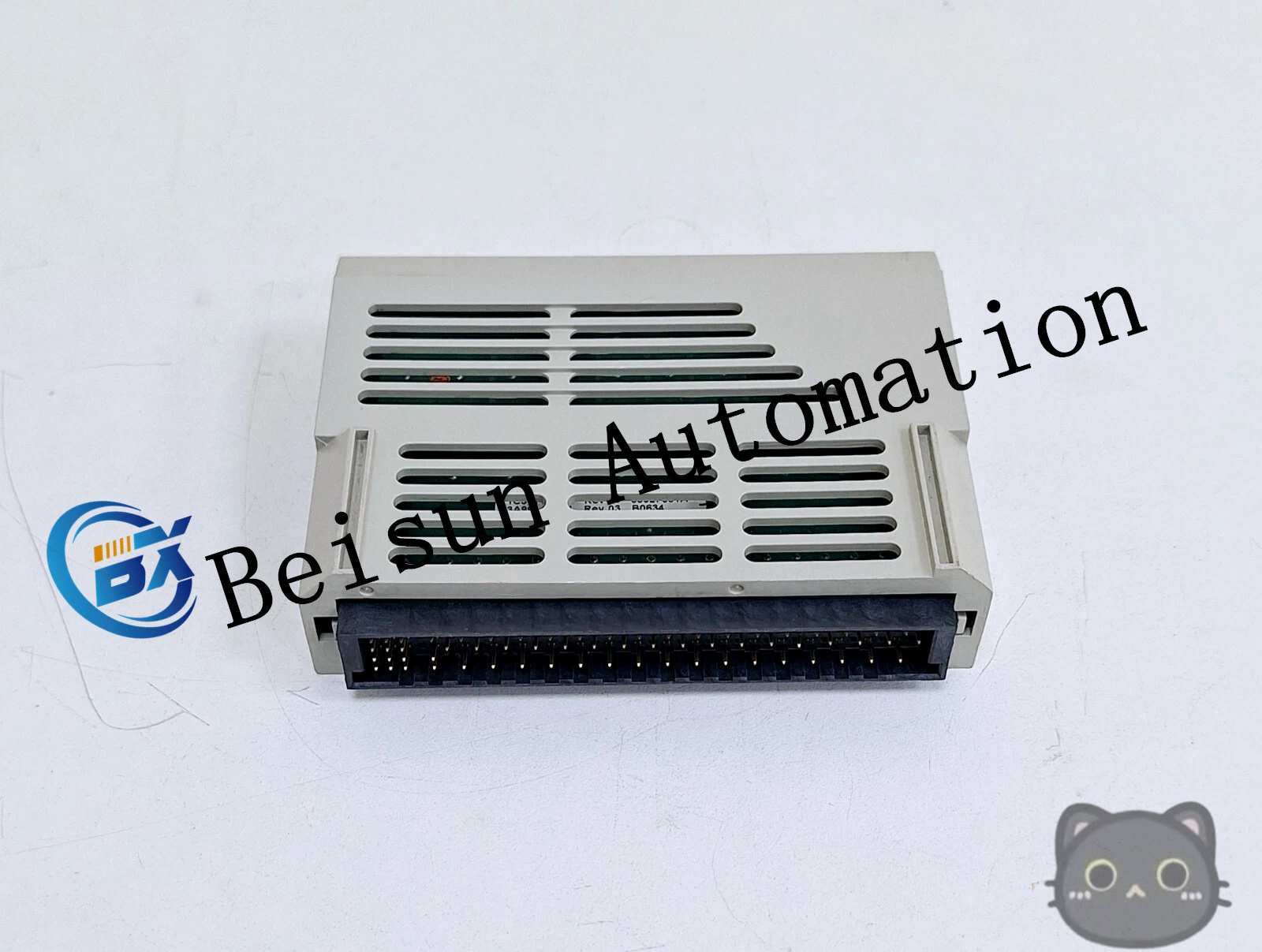

Emerson 1C31110G02 Digital input module

Main performance

Input signal type: 125V AC/DC differential digital input signal, capable of receiving dry contact or wet contact signals.

Number of channels: Usually 16 channels, it can simultaneously connect 16 on-site devices to achieve simultaneous monitoring of the status of multiple devices.

Electrical isolation: Electrical isolation technology is adopted between the input channel and the internal circuit, which can effectively prevent external electrical interference from entering the control system and avoid the impact of module failures on external devices at the same time.

Protection function: It has a signal conditioning function, which can dissipate voltage “spikes” and protect electronic components. When there is a short circuit in the on-site equipment circuit, the fuse can protect the circuit.

Hot plugging function: It supports hot plugging, allowing modules to be removed and replaced without interrupting the system power supply or using mechanical tools, which is convenient for system maintenance and upgrade.

Application field

Oil refinery: In the oil refining production process, it is used to monitor the on-off status of various process valves, the operating status of pumps and compressors, temperature and pressure, and other alarm signals. The 1C31110G02 module can promptly detect fault signals and transmit them to the control system, enabling corresponding measures to be taken, such as starting the standby pump or halting the relevant process flow, to prevent production accidents.

Non-ferrous metal smelting plant: It is used to monitor alarm signals such as temperature and pressure of the furnace, as well as the operating status signals of material conveying equipment. This information is of great significance for optimizing the smelting process and ensuring production safety.

Pharmaceutical factory: During the drug production process, by monitoring the working status signals of the filling machine, the control system can grasp the accuracy and stability of the filling process in real time, promptly identify and correct issues such as inaccurate filling volume, and ensure that the quality of the drugs meets the standards.

Reviews

There are no reviews yet.