Product information

Reviews

Shipping & returns

Product information

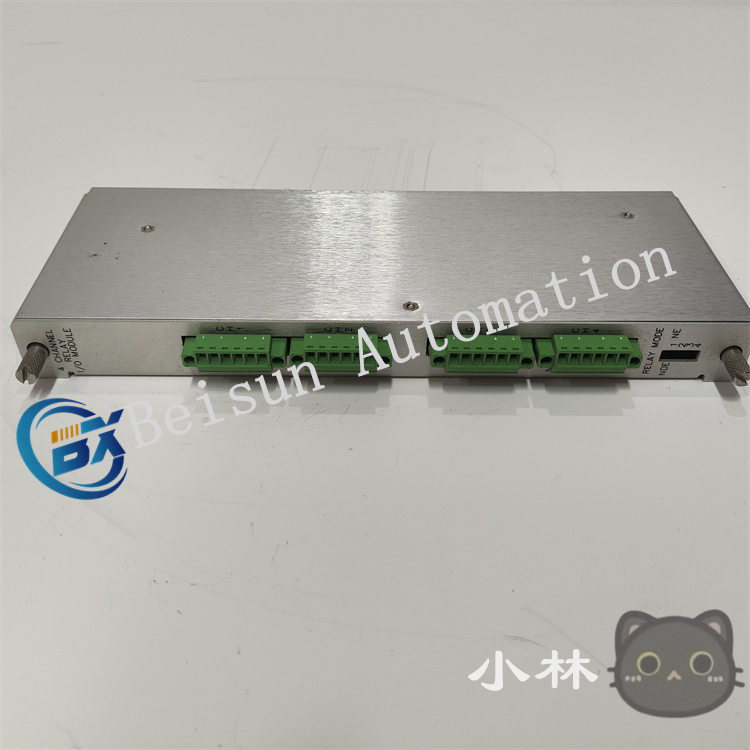

GE 369-HI-R-0-0-E-0-E Series 369 motor management relays

Protection function

Overload protection: The motor current can be monitored, and when the current exceeds the set overload threshold, timely measures can be taken to protect the motor and prevent the motor from being damaged due to long-term overload operation.

Phase sequence protection: detect the phase sequence of the power supply, if the phase sequence is wrong, relay action, to avoid the motor due to reverse phase sequence or damage.

Grounding fault protection: the motor grounding fault is monitored, and once the grounding fault current is detected, the circuit is quickly cut off to ensure the safety of personnel and equipment.

Short-circuit protection: It can quickly respond to the short-circuit fault in the motor circuit, cut off the power supply in a very short time, and prevent the short-circuit current from causing serious damage to the motor and other equipment.

Unbalance protection: Monitor the balance of three-phase current, when there is an unbalance of current, such as single-phase operation, timely alarm or tripping, to protect the motor from the harm of unbalanced current.

Control function

Multiple start control: The starting times and time intervals of the motor can be set to meet the starting requirements of the motor in different application scenarios and avoid the damage caused by frequent starting of the motor.

Stator windings and bearings overheat protection: The thermal model is biased by RTD and negative sequence current feedback to monitor the temperature of stator windings and bearings in real time, and take protective measures to prevent overheating damage when the temperature exceeds the set value.

Monitoring and metering functions

Optional voltage and power metering: The voltage and power parameters of the motor can be measured to provide users with electrical parameter information for motor operation, which is convenient for energy management and fault diagnosis.

Learning and statistical data: with data learning and statistical functions, can record motor operation data, such as running time, startup times, etc., for motor maintenance and management to provide a reference basis.

Data logger: It can record key data during the operation of the motor, such as the current, voltage and other information when the fault occurs, which is convenient for users to analyze and troubleshoot the fault.

Reviews

There are no reviews yet.