- Home

- Product

- Bently Nevada

- BENTLY 330101-00-08-05-02-05 Eddy current sensor

Product information

Reviews

Shipping & returns

Product information

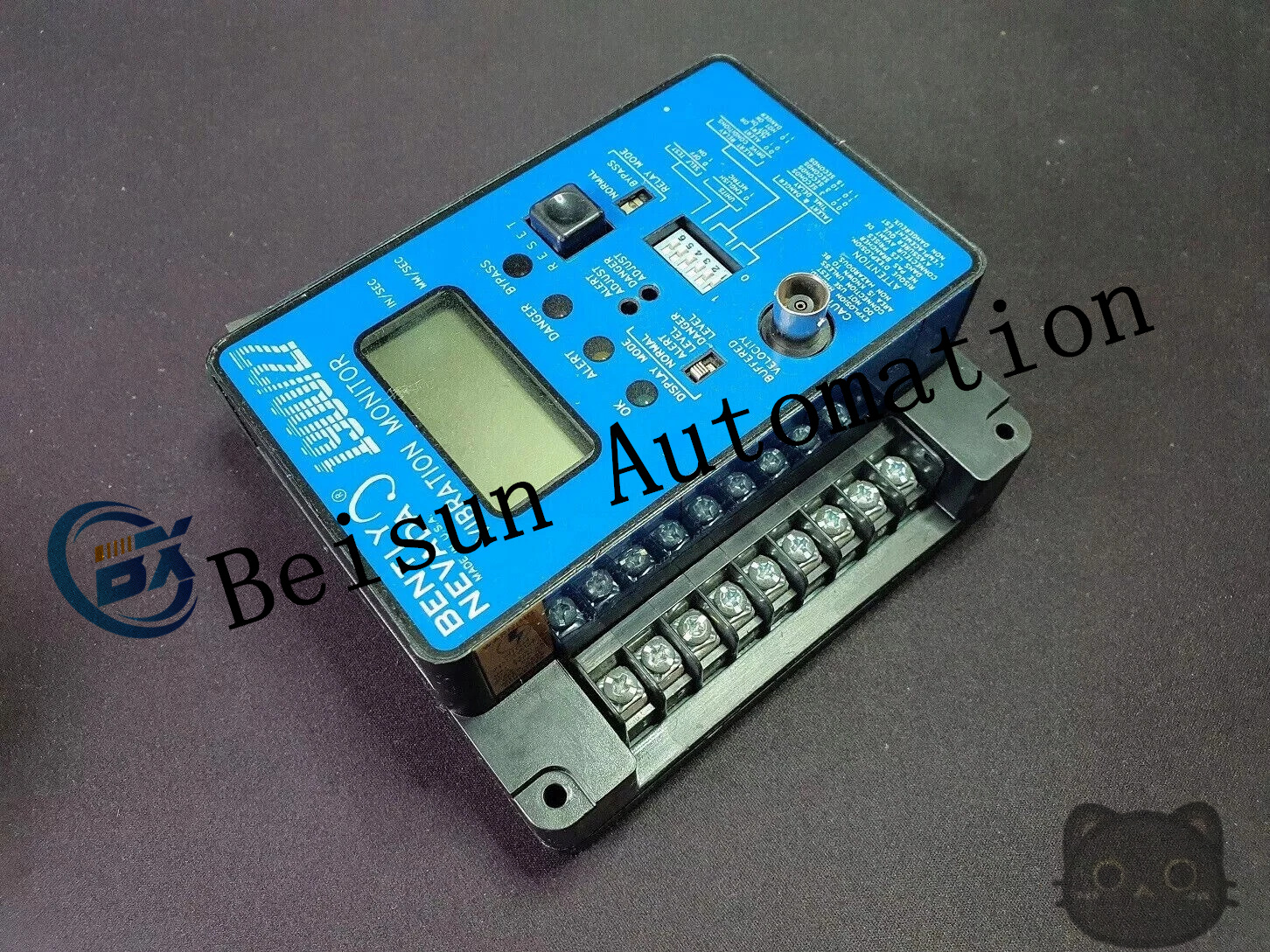

BENTLY 330101-00-08-05-02-05 Eddy current sensor

Series and type: 3300 XL series 8mm eddy current sensor probe, used to measure the vibration, displacement and other parameters of rotating machinery.

Working principle: Based on the eddy current effect, the sensor probe generates a high-frequency magnetic field, and when it is close to the conductive metal surface, the eddy current is induced on the metal surface, and the magnetic field generated by the eddy current reacts on the probe, so that the probe coil impedance changes, by measuring the change of the distance between the probe and the metal surface, and then the measurement of the object displacement, vibration and other parameters.

Size and weight: The size is about 20.5cm×22.4cm×3.3cm, the weight is 0.1kg.

Technical parameters:

Measuring range: 0.1mm to 2mm for precise measurement of small displacement changes.

Sensitivity: 0.1μm/division, can capture subtle vibration or displacement signals.

Output type: 4-20mA current signal, easy to connect with industrial control system interface.

Operating temperature: -40℃ to + 100℃, suitable for a variety of harsh industrial environment.

Protection grade: IP67, dustproof, waterproof performance is good, can operate reliably in wet, dusty environment.

Installation method: non-contact installation, will not disturb or damage the object under test, easy to integrate into the rotating equipment.

Functional features:

High-precision measurement: Advanced electronic circuits and signal processing technology provide high-precision measurement results to help accurately evaluate equipment operating status.

Strong anti-interference ability: with good electromagnetic compatibility, can effectively inhibit external electromagnetic interference, to ensure stable work in complex industrial electromagnetic environment.

High durability: The use of high-quality stainless steel materials and injection molding housing, high temperature resistance, impact resistance, can be long-term stable operation in harsh industrial environments.

Application: It is mainly used for vibration monitoring and shaft displacement measurement of rotating machinery in various industrial scenarios, such as steam turbines, generators, compressors, pumps, fans, etc. By monitoring these key parameters in real time, the abnormal running status of the device can be discovered in time, which provides an important basis for preventive maintenance of the device.

Reviews

There are no reviews yet.