- Home

- Product

- Bently Nevada

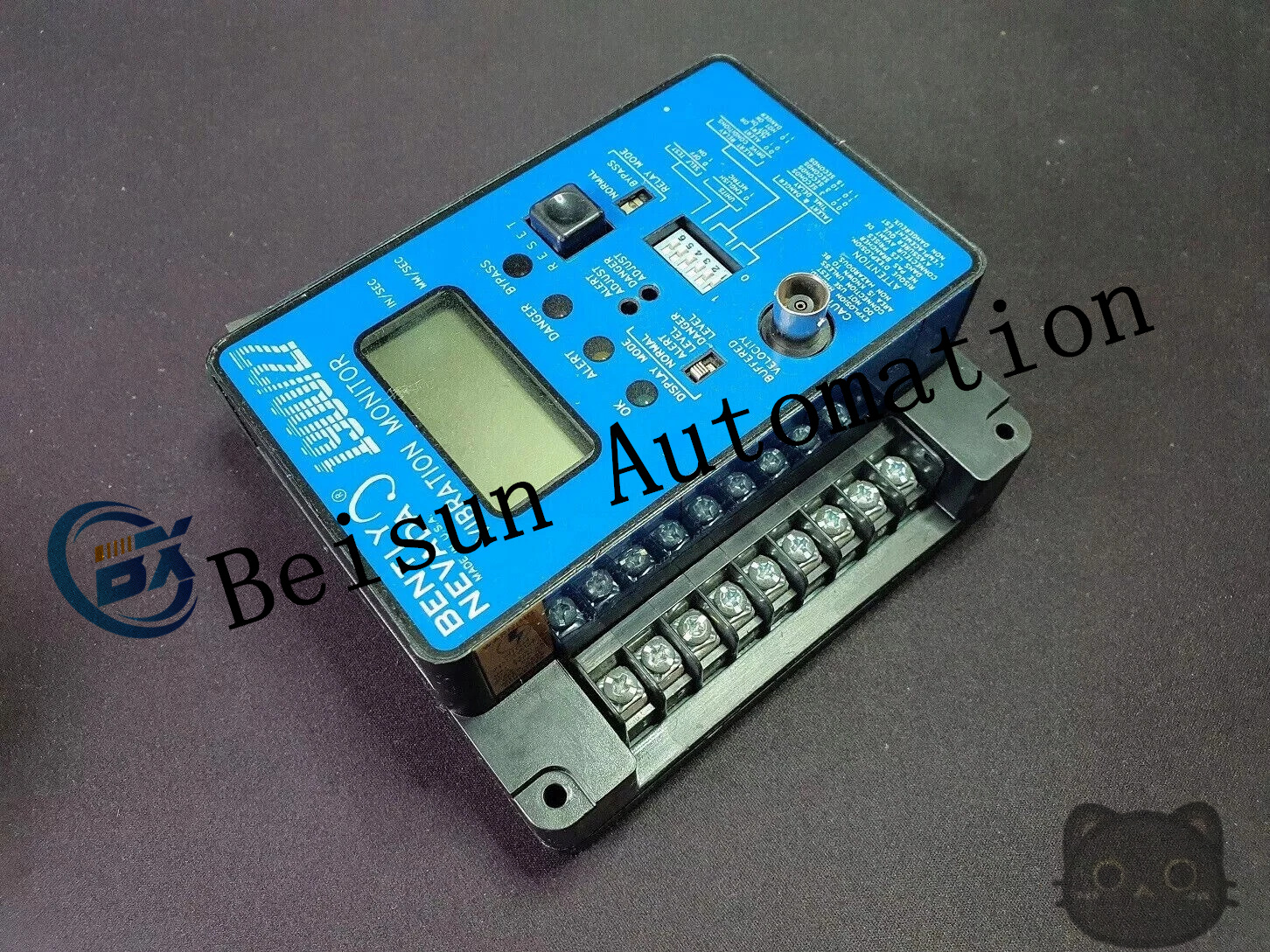

- BENTLY 3300/05-23-00-00 Single channel eddy current proximity probe

Product information

Reviews

Shipping & returns

Product information

BENTLY 3300/05-23-00-00 Single channel eddy current proximity probe

How it works: The position and vibration of the axis of rotation are measured by measuring the eddy currents induced by the probe magnetic field in the conductive target. The target can be the shaft itself, the sleeve attached to the shaft, or any other conductive material near the shaft.

Specification parameter

Frequency range: 0 to 10kHz.

Output voltage: 0 to 10Vdc.

Input voltage: 24Vdc.

Ambient temperature: -40℃ to + 85℃.

Storage temperature: -50℃ to + 90℃.

Vibration: 2g rms, 20 to 500Hz.

Impact: 20g peak, 11ms duration.

Functional characteristics

Non-contact measurement: avoids direct contact with rotating parts, reduces wear and interference with equipment, and improves measurement accuracy and equipment reliability.

High accuracy: The ability to provide accurate measurement results helps to detect small changes and potential failures of equipment in a timely manner.

Wide measurement range: can adapt to different measurement needs, covering a variety of industrial scenarios, axis displacement, vibration and other parameters measurement.

Easy installation and maintenance: The design structure is easy to install on a variety of equipment, and the daily maintenance work is relatively simple, reducing maintenance costs and downtime.

High reliability: Using high-quality materials and advanced manufacturing processes, it can work stably in harsh industrial environments, ensuring long-term reliable measurement performance.

Application field

Turbine position monitoring: Real-time monitoring of the position and vibration of the turbine shaft to ensure the normal operation of the turbine and prevent failure caused by excessive shaft displacement or vibration.

Generator position monitoring: Accurate measurement of the position and vibration of the generator rotor, timely detection of potential problems, to ensure stable generation of the generator.

Compressor position monitoring: Monitoring the status of the compressor shaft helps to optimize the operating parameters of the compressor, improve its efficiency and reliability, and avoid production accidents caused by shaft failure.

Pump position monitoring: It is used to monitor the position and vibration of the pump shaft, find the abnormal situation of the pump in time, carry out maintenance and repair in advance, and reduce the damage and downtime of the pump.

Fan position monitoring: monitoring the operating status of the fan shaft to ensure the safe operation of the fan and improve the service life and work efficiency of the fan.

Reviews

There are no reviews yet.