- Home

- Product

- Bently Nevada

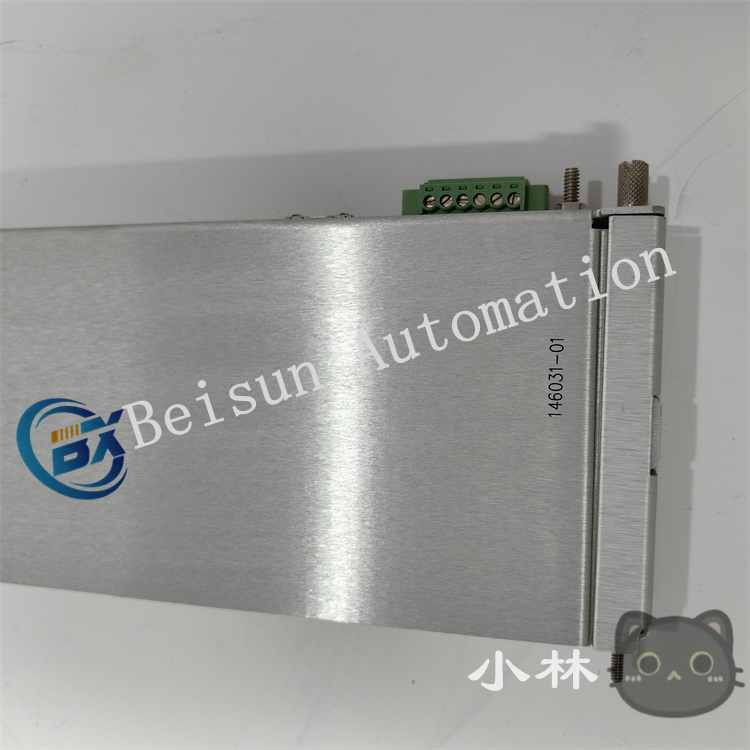

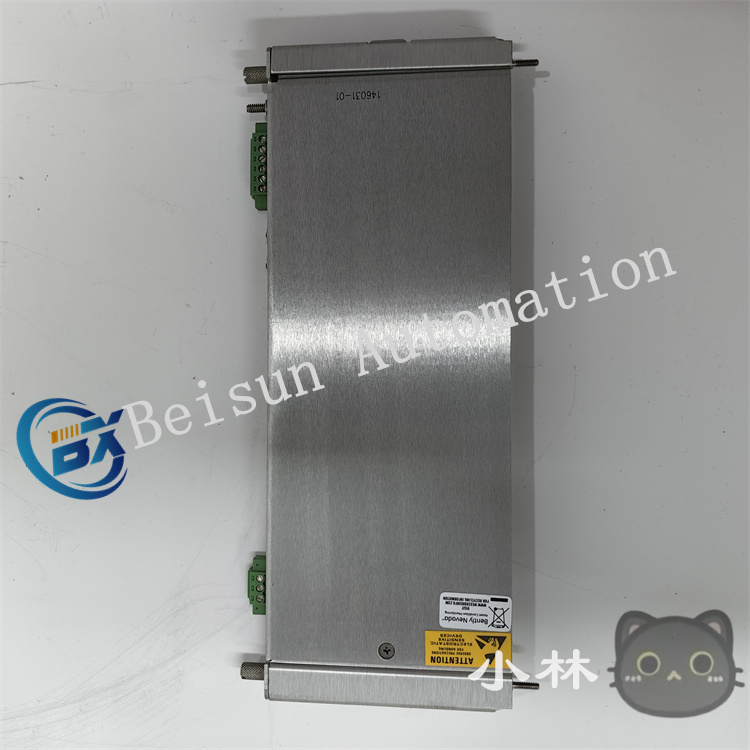

- BENTLY 3500/22M 146031-01 3500 series transient data interface module

Product information

Reviews

Shipping & returns

Product information

BENTLY 3500/22M 146031-01 3500 series transient data interface module

Functional characteristics

Interface: The interface between the 3500 monitoring System and the Bentley Nevada System 1TM machine management software integrates the functions of the 3500/20 Framework interface module (RIM) and communication processors such as TDXnet.

Data acquisition and transmission: Located in the first slot of the 3500 frame (next to the power module), it works with the M series monitors (e.g. 3500/40M, 3500/42M, etc.) to continuously collect steady-state and transient waveform data and transmit the data to the main computer software over Ethernet. It has static data collection by default, and can also collect transient or dynamic data by installing an optional channel to enable the disk.

Special Features: For triple module redundancy (TMR) applications, in addition to the standard TDI function, the TMR version of TDI performs a “monitor channel comparison” function to compare the output of three redundant monitors in real time, and if the output information of one monitor is found to be unequal to that of the other two (within a percentage range of configurations), the output information of the three redundant monitors can be compared in real time. An error is indicated to the monitor and an event is logged in the system event list.

Technical parameter

Input signal range: -10Vdc to + 10Vdc.

Power consumption: 10.5W.

Operating temperature: -30℃ to + 65℃.

Size: 241.3 mm ×24.4 mm ×241.8 mm.

Weight: 0.82 kg (1.8 lb).

Ethernet: Supports 100Base-FX fiber.

Application scenario: It is mainly used in the condition monitoring and fault diagnosis system of key rotating machinery and equipment in the industrial field, such as the vibration monitoring and analysis of steam turbines and generators in the power industry, compressors and pumps in the petrochemical industry, and large fans in the metallurgical industry, to provide accurate data support for the maintenance and maintenance of the equipment and ensure the safe and stable operation of the equipment.

Reviews

There are no reviews yet.