- Home

- Product

- Bently Nevada

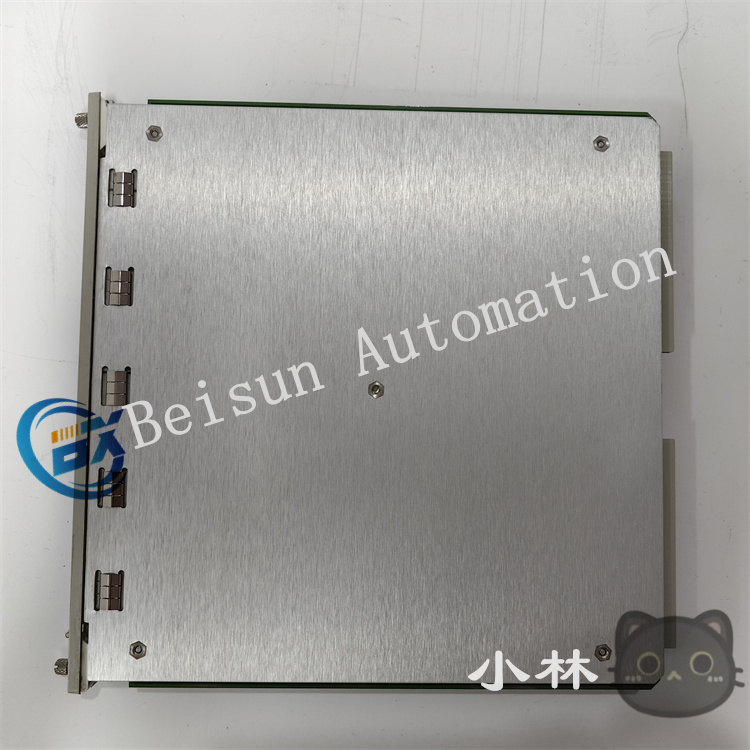

- Bently Nevada 3500/20-01-02-00 3500 series frame interface module

Product information

Reviews

Shipping & returns

Product information

Bently Nevada 3500/20-01-02-00 3500 series frame interface module

Functional role

Configuration and retrieval: Supports proprietary protocols for configuring 3500 racks and retrieving machine information, which can be read and written to rack and machine information.

Connected communication processor: The Bently Nevada communication processor, which is compatible with TDXnet, TDIX, and DDIX, enables data communication and information exchange, ensuring efficient data transfer between systems.

Provide read-only access: Provide read-only access for users to view rack and machine information, but restrict the writing or modification of the configuration, helping to protect the stability and security of the system configuration.

Password protection: Stores configuration passwords and can communicate with 3500 rack only if the entered password matches the password in the rack configuration software, enhancing system security and preventing unauthorized access and configuration changes.

Technical parameter

Size: about 16cm×16cm×12cm.

Weight: About 0.8kg.

Interface type: Usually with RS232, RS422 and other interfaces, can realize the connection with other devices and data transmission.

Operating temperature range: generally -40 °C to + 70°C, can adapt to a variety of different working environments.

Protection level: IP20, can prevent the intrusion of objects greater than 12.5mm, suitable for general industrial environment.

Application field

Industrial automation: Used to monitor and protect critical equipment, such as motors, pumps, fans, etc. on production lines, helping to improve equipment operation efficiency and production safety, reducing downtime and maintenance costs.

Power generation: Vibration monitoring and fault diagnosis can be carried out on key equipment such as generators and steam turbines to ensure the stable operation of power production equipment and ensure the reliability of power supply.

Petrochemical: In the petrochemical industry, it is often used to monitor the vibration of rotating machinery such as pumps, compressors, centrifuges, and so on, to discover hidden dangers of equipment failure in time, and to avoid production accidents and economic losses caused by equipment failure.

Manufacturing: Suitable for machine tool control and process control, to help manufacturers improve production accuracy and product quality, while reducing equipment maintenance costs, improve production efficiency.

Other fields: It can also be used in aerospace, shipbuilding, metallurgy and other fields requiring high-precision vibration monitoring and equipment protection to provide guarantee for the safe operation of equipment.

Reviews

There are no reviews yet.